Industrial Blenders

Description:

Introducing our Industrial Blender—an advanced and versatile solution designed to meet the demanding blending needs of various industries. Our Industrial Blender combines cutting-edge technology with robust construction to deliver efficient and consistent blending performance, making it a go-to choice for businesses worldwide.

Download Brochure

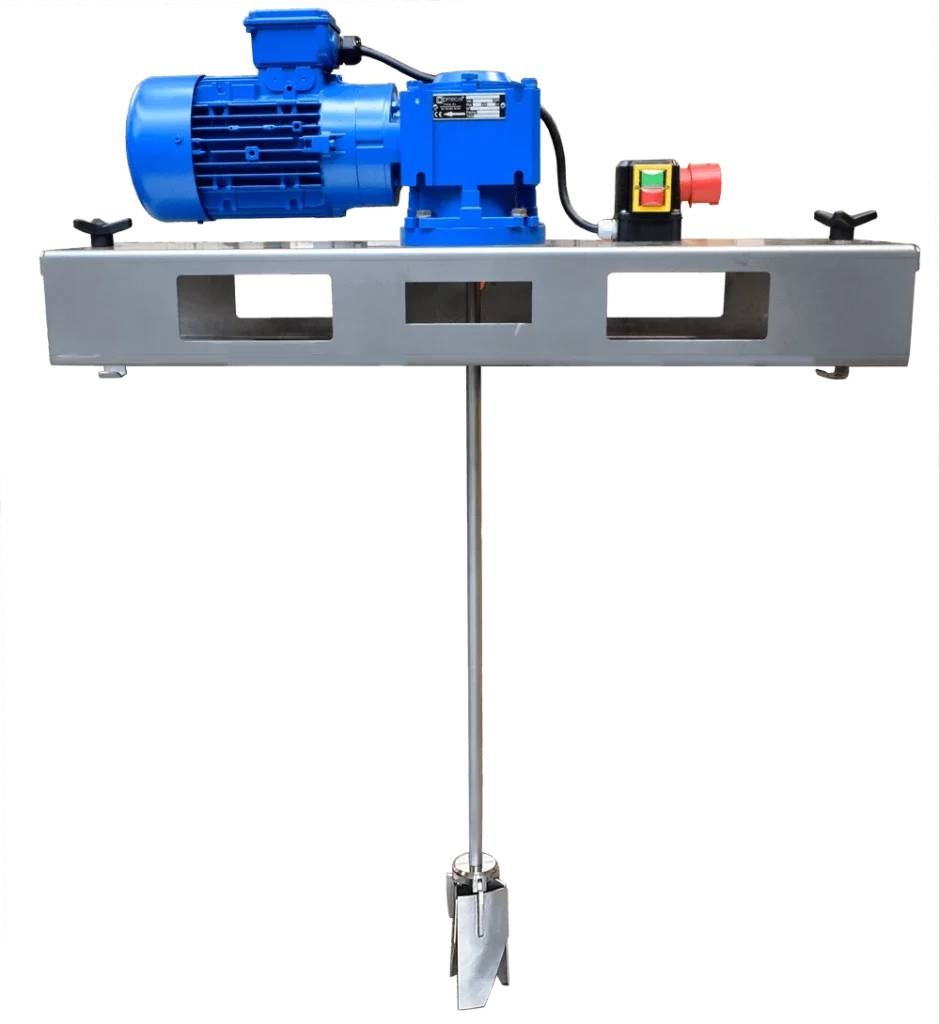

Powerful Blending Capability:

The Industrial Blender boasts a high-powered motor and precision-engineered blades, enabling it to handle a wide range of blending tasks with ease. From dry powders and granules to viscous liquids and pastes, this blender ensures thorough and uniform mixing for optimal product consistency.

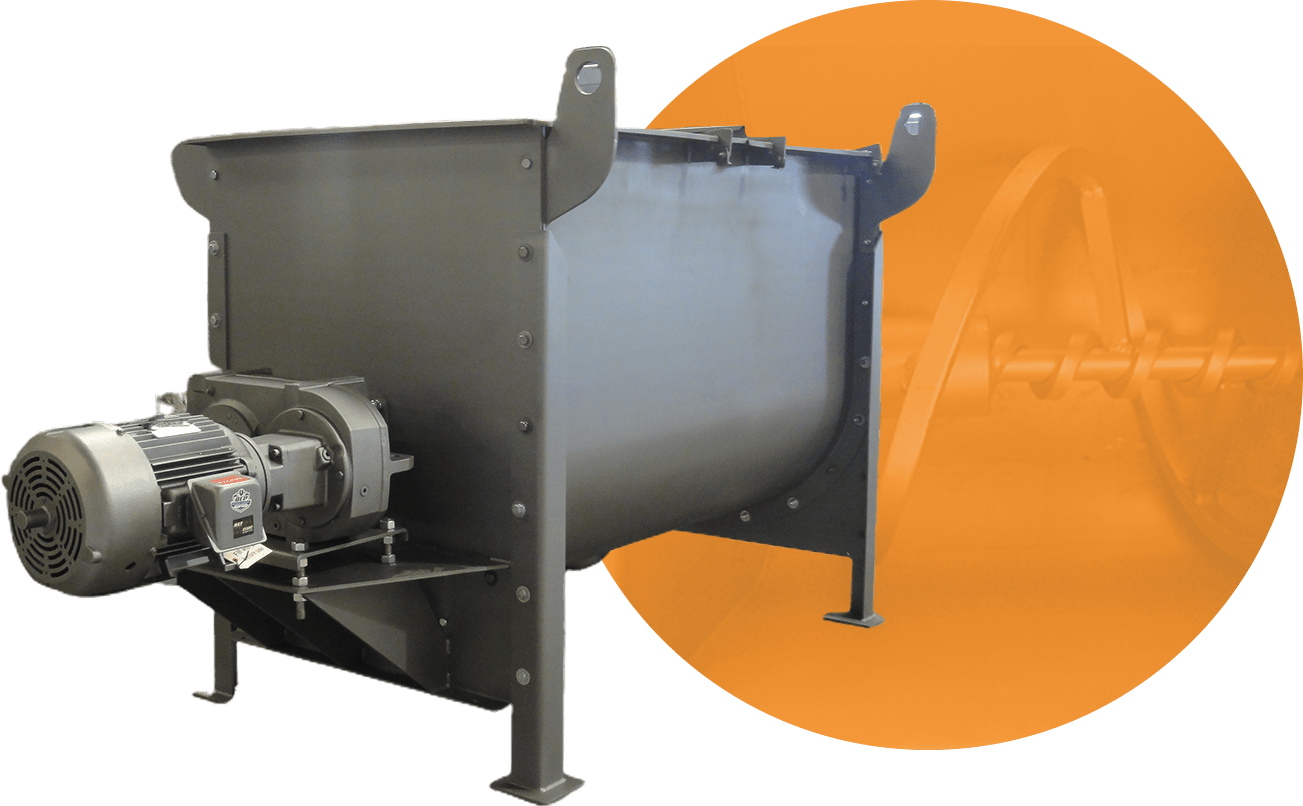

Versatile Design:

Our Industrial Blender is designed to accommodate different batch sizes and ingredients, making it suitable for diverse production requirements. With customizable settings, you can adjust blending parameters to achieve the desired texture, homogeneity, and particle size distribution.

Robust Construction: Built to withstand rigorous industrial environments, our Industrial Blender is constructed using durable materials that ensure long-lasting performance. Its sturdy design minimizes vibrations, enhances stability, and guarantees reliable operation even under heavy-duty usage.

User-Friendly Interface:

The Industrial Blender features an intuitive control panel that simplifies operation and allows for precise adjustments. With user-friendly interfaces and programmable settings, operators can easily monitor and control blending processes, ensuring consistent results every time.

Safety and Efficiency: Safety is paramount in industrial settings, and our Industrial Blender is equipped with safety mechanisms such as overload protection and emergency stop features. Additionally, it is designed for efficient operation, minimizing downtime and maximizing productivity.

Easy Maintenance:

We understand the importance of hassle-free maintenance. Our Industrial Blender incorporates easy-to-clean components and quick disassembly features, making cleaning and maintenance tasks straightforward and time-saving.

Wide Industry Applications:

The Industrial Blender finds applications across a wide range of industries, including food and beverage, pharmaceuticals, chemicals, and cosmetics. Its versatility and adaptability make it an essential tool for blending ingredients, powders, and formulations in various manufacturing processes.

Discover the power and efficiency of our Industrial Blender to elevate your blending capabilities and optimize your production processes. With its powerful performance, versatile design, and user-friendly operation, our Industrial Blender is the perfect solution for achieving consistent and high-quality blends. Contact us today to learn more about how our Industrial Blender can enhance your manufacturing operations.

Keywords:

industrial blender, blending, mixing, versatile design, powerful blending capability, robust construction, user-friendly interface, safety, efficiency, easy maintenance, wide industry applications, industrial mixing, batch blending, product consistency, manufacturing operations, high-quality blends.

· · Specifications:

Ø Capacity:

Available in a range of capacities to suit various production needs (e.g., 100 liters, 500 liters, 1000 liters, etc.).

Customizable options for larger or smaller capacities upon request.

Ø Power:

High-powered motor for efficient blending performance.

Motor power may vary based on the blender's capacity (e.g., 5 HP, 10 HP, 20 HP, etc.).

Configurable voltage options to align with regional electrical standards.

Ø Blending Mechanism:

Precision-engineered blades designed to handle a wide range of ingredients and achieve consistent blending results.

Options for different blade types (e.g., paddle blades, ribbon blades, spiral blades) to cater to specific blending requirements.

Adjustable blending speed and intensity settings to achieve desired texture and homogeneity.

Ø Construction:

Robust and durable construction using high-quality materials to withstand heavy-duty usage.

Stainless steel or food-grade materials for parts that come into contact with ingredients to ensure product safety and hygiene.

Sturdy base and frame to minimize vibrations and enhance stability during operation.

Ø Control Panel:

User-friendly interface with intuitive controls for easy operation.

Digital display for monitoring blending parameters, such as time, speed, and temperature (if applicable).

Programmable settings to store and recall specific blending profiles for consistent results.

Ø Safety Features:

Overload protection to prevent motor burnout and equipment damage.

Emergency stop button for immediate cessation of blending operations.

Safety interlocks and guards to ensure operator protection during operation.

Ø Cleaning and Maintenance:

Easy-to-clean design with smooth surfaces and quick disassembly features for efficient cleaning.

Removable components (e.g., blades, container) for thorough maintenance and sanitation.

Regular maintenance recommendations provided in the user manual for optimal performance and longevity.

Ø Applications:

Versatile applications in industries such as food and beverage, pharmaceuticals, chemicals, cosmetics, and more.

Suitable for blending dry powders, granules, liquids, pastes, and other ingredients.

Please note that the specifications provided are general and can be customized based on specific customer requirements.