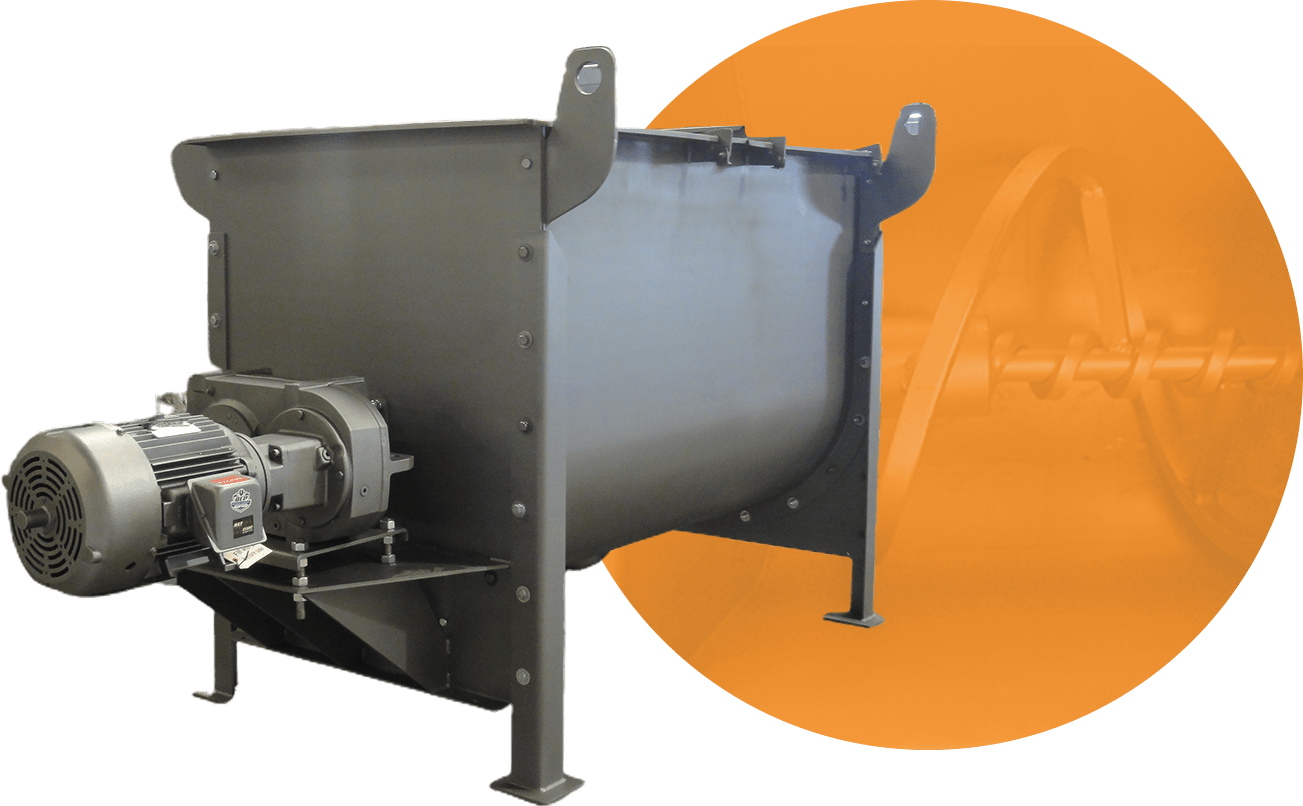

Industrial Agitator

Flash Mixer

Description:

Introducing our Flash Mixer Agitator—an essential component for efficient mixing and blending in various industrial applications. With its advanced features and reliable performance, our Flash Mixer Agitator ensures rapid and thorough mixing, delivering consistent results every time.

Download BrochureRapid Mixing Capability:

The Flash Mixer Agitator is specifically designed for quick and efficient mixing, achieving rapid dispersion and homogenization of materials. It facilitates high-speed mixing, reducing process time and enhancing productivity.

Versatile Design:

Our Flash Mixer Agitator is available in different sizes and configurations, accommodating diverse batch sizes and production requirements. It offers flexibility in terms of adjustable mixing parameters, allowing precise control over mixing intensity and duration.

Robust Construction:

Built to withstand demanding industrial environments, our Flash Mixer Agitator is constructed using durable materials, ensuring long-lasting performance. Its sturdy design minimizes vibrations, enhances stability, and guarantees reliable operation even under heavy-duty usage.

Adjustable Parameters:

The Flash Mixer Agitator provides customizable options for adjusting mixing parameters, such as rotational speed and mixing time. This allows for fine-tuning of the mixing process, ensuring optimal blending and homogenization of materials.

Easy Installation and Operation:

Our Flash Mixer Agitator features a user-friendly design, making installation and operation hassle-free. It is designed for easy integration into existing systems, minimizing downtime and facilitating seamless operation.

Safety Features:

Safety is paramount, and our Flash Mixer Agitator is equipped with safety mechanisms to protect operators and prevent accidents. It includes features such as overload protection and emergency stop functions, ensuring operator safety during operation and maintenance.

Wide Industry Applications:

The Flash Mixer Agitator finds applications across various industries, including wastewater treatment, chemical processing, food and beverage, and more. Its versatility makes it suitable for blending and mixing liquids, powders, and other materials in different manufacturing processes.

Experience the exceptional mixing capabilities of our Flash Mixer Agitator to enhance your production processes and achieve superior results. With its rapid mixing capability, versatile design, and user-friendly operation, our Flash Mixer Agitator is the perfect solution for your blending needs. Contact us today to learn more about how our Flash Mixer Agitator can optimize your manufacturing operations.

Keywords:

flash mixer agitator, rapid mixing, blending, versatile design, robust construction, adjustable parameters, easy installation, user-friendly operation, safety features, wide industry applications, wastewater treatment, chemical processing, food and beverage, material homogenization, manufacturing operations.

Ø Mixing Capacity:

Designed to efficiently mix and blend materials in various industrial applications.

Available in different capacities to suit different batch sizes and production requirements.

Ø Motor Power:

Powerful motor for rapid and thorough mixing performance.

Motor power options may vary (e.g., 1 HP, 3 HP, 5 HP, etc.) depending on the specific agitator model and application requirements.

Ø Mixing Mechanism:

Specially designed impeller or mixing blades for efficient dispersion and homogenization of materials.

Flash mixing capability to achieve rapid and uniform mixing results.

Ø Construction:

Sturdy construction using durable materials (e.g., stainless steel, coated alloys) to withstand demanding industrial environments.

Resilient design to minimize vibrations and ensure stable operation during the mixing process.

Ø Adjustable Parameters:

Variable speed control to adjust the agitator's rotational speed for precise control over mixing intensity and duration.

Customizable mixing time settings to optimize the mixing process and achieve desired blending results.

Ø Mounting and Installation:

Easy and secure mounting on tanks, vessels, or mixing containers.

Various mounting options available, such as flange mounting or clamp mounting, to accommodate different equipment configurations.

Ø Control Panel:

User-friendly control panel for convenient operation and adjustment of mixing parameters.

Intuitive controls for starting, stopping, and adjusting the agitator's speed or other relevant functions.

Ø Safety Features:

Safety interlocks and guards to ensure operator protection during installation, maintenance, and operation.

Emergency stop button for immediate shutdown in case of emergencies or unforeseen situations.

Ø Maintenance:

Easy-to-access design for routine maintenance and cleaning.

Regular maintenance recommendations provided in the user manual for optimal performance and longevity.

Ø Applications:

Suitable for a wide range of industries, including wastewater treatment, chemical processing, food and beverage, and more.

Ideal for blending and mixing liquids, powders, and other materials to achieve uniformity and desired consistency.

Please note that the specifications provided are general and can be customized based on specific customer requirements and the intended applicationSuperior Flocculation Performance:

The Flocculator Agitator employs advanced technology to ensure optimal flocculation of suspended particles in wastewater. It generates the ideal mixing conditions to facilitate the aggregation of fine particles into larger flocs, allowing for easier separation and improved water quality.

Robust Construction:

Built with durability in mind, the Flocculator Agitator is constructed from high-quality materials that are resistant to corrosion and wear. Its sturdy design ensures reliable performance even in demanding wastewater treatment environments.

Customizable Design:

We understand that every wastewater treatment plant has unique requirements. Therefore, our Flocculator Agitator can be customized to meet specific operational needs. From size and power to impeller configuration, we offer flexibility in tailoring the agitator to your plant's specifications.

Energy-Efficient Operation:

The Flocculator Agitator is engineered to minimize energy consumption without compromising performance. Its efficient motor and streamlined design reduce power requirements, resulting in significant energy savings for your wastewater treatment facility.

Easy Maintenance:

We recognize the importance of hassle-free maintenance in maximizing uptime and minimizing operational disruptions. With its accessible design and user-friendly features, the Flocculator Agitator simplifies maintenance tasks, ensuring smooth operation and reducing downtime.

Safety and Compliance:

Safety is our top priority. The Flocculator Agitator adheres to industry safety standards and incorporates safety mechanisms to protect both operators and the surrounding environment. It is designed to meet or exceed all relevant regulatory requirements for wastewater treatment equipment.

Seamless Integration:

Our Flocculator Agitator is designed to seamlessly integrate into existing wastewater treatment systems. Whether you're upgrading your current setup or building a new facility, our expert team will work closely with you to ensure a smooth installation and integration process.

Benefit from the Flocculator Agitator's advanced technology and robust performance to enhance the efficiency and effectiveness of your wastewater treatment processes. Experience improved water quality, reduced operational costs, and greater environmental sustainability. Contact us today to learn more about how the Flocculator Agitator can transform your wastewater treatment operations.

Keywords:

flocculator agitator, wastewater treatment, flocculation, impurity removal, water quality, durable construction, customizable design, energy-efficient, easy maintenance, safety and compliance, seamless integration, improved water quality, operational cost reduction, environmental sustainability.

· Ø Flocculation Capacity:

Designed to efficiently promote flocculation in wastewater treatment processes.

Capacity options available to suit different flow rates and treatment volumes.

Ø Motor Power:

Powerful motor for effective agitation and generation of optimal mixing conditions.

Motor power options may vary (e.g., 1 HP, 3 HP, 5 HP, etc.) depending on the specific agitator model and application requirements.

Ø Mixing Mechanism:

Specialized impeller design to facilitate the aggregation of fine particles into larger flocs.

Impeller configuration optimized for promoting flocculation and ensuring uniform mixing throughout the wastewater.

Ø Construction:

Sturdy construction using corrosion-resistant materials (e.g., stainless steel, coated alloys) to withstand harsh wastewater treatment environments.

Resilient design to withstand abrasion, chemicals, and other factors that can impact performance and longevity.

Ø Adjustable Parameters:

Variable speed control to adjust the agitator's rotational speed and intensity of mixing.

Customizable impeller design options (e.g., paddle, propeller, turbine) to meet specific flocculation requirements.

Ø Mounting and Installation:

Easy and secure mounting on tanks, basins, or other wastewater treatment vessels.

Options for different mounting configurations (e.g., vertical, horizontal) based on the system layout and space constraints.

Ø Control Panel:

User-friendly control panel for convenient operation and adjustment of mixing parameters.

Intuitive controls for starting, stopping, and adjusting the agitator's speed or other relevant functions.

Ø Safety Features:

Safety mechanisms to protect operators and prevent accidents during installation, maintenance, and operation.

Emergency stop button for immediate shutdown in case of emergencies or unforeseen situations.

Ø Maintenance:

Easy-to-access design for routine maintenance and cleaning.

Regular maintenance recommendations provided in the user manual for optimal performance and longevity.

Ø Applications:

Suitable for a range of wastewater treatment processes, including municipal wastewater treatment plants, industrial wastewater treatment facilities, and more.

Specifically designed for promoting flocculation and facilitating the removal of impurities from wastewater.

Please note that the specifications provided are general and can be customized based on specific customer requirements and the intended application.

IBC Stirrer

...

IBC Stirrer Machine.

Industrial Blenders

Description:

Introducing our Industrial Blender—an advanced and versatile solution designed to meet the demanding blending needs of various industries. Our Industrial Blender combines cutting-edge technology with robust construction to deliver efficient and consistent blending performance, making it a go-to choice for businesses worldwide.

Download BrochurePowerful Blending Capability:

The Industrial Blender boasts a high-powered motor and precision-engineered blades, enabling it to handle a wide range of blending tasks with ease. From dry powders and granules to viscous liquids and pastes, this blender ensures thorough and uniform mixing for optimal product consistency.

Versatile Design:

Our Industrial Blender is designed to accommodate different batch sizes and ingredients, making it suitable for diverse production requirements. With customizable settings, you can adjust blending parameters to achieve the desired texture, homogeneity, and particle size distribution.

Robust Construction: Built to withstand rigorous industrial environments, our Industrial Blender is constructed using durable materials that ensure long-lasting performance. Its sturdy design minimizes vibrations, enhances stability, and guarantees reliable operation even under heavy-duty usage.

User-Friendly Interface:

The Industrial Blender features an intuitive control panel that simplifies operation and allows for precise adjustments. With user-friendly interfaces and programmable settings, operators can easily monitor and control blending processes, ensuring consistent results every time.

Safety and Efficiency: Safety is paramount in industrial settings, and our Industrial Blender is equipped with safety mechanisms such as overload protection and emergency stop features. Additionally, it is designed for efficient operation, minimizing downtime and maximizing productivity.

Easy Maintenance:

We understand the importance of hassle-free maintenance. Our Industrial Blender incorporates easy-to-clean components and quick disassembly features, making cleaning and maintenance tasks straightforward and time-saving.

Wide Industry Applications:

The Industrial Blender finds applications across a wide range of industries, including food and beverage, pharmaceuticals, chemicals, and cosmetics. Its versatility and adaptability make it an essential tool for blending ingredients, powders, and formulations in various manufacturing processes.

Discover the power and efficiency of our Industrial Blender to elevate your blending capabilities and optimize your production processes. With its powerful performance, versatile design, and user-friendly operation, our Industrial Blender is the perfect solution for achieving consistent and high-quality blends. Contact us today to learn more about how our Industrial Blender can enhance your manufacturing operations.

Keywords:

industrial blender, blending, mixing, versatile design, powerful blending capability, robust construction, user-friendly interface, safety, efficiency, easy maintenance, wide industry applications, industrial mixing, batch blending, product consistency, manufacturing operations, high-quality blends.

· · Specifications:

Ø Capacity:

Available in a range of capacities to suit various production needs (e.g., 100 liters, 500 liters, 1000 liters, etc.).

Customizable options for larger or smaller capacities upon request.

Ø Power:

High-powered motor for efficient blending performance.

Motor power may vary based on the blender's capacity (e.g., 5 HP, 10 HP, 20 HP, etc.).

Configurable voltage options to align with regional electrical standards.

Ø Blending Mechanism:

Precision-engineered blades designed to handle a wide range of ingredients and achieve consistent blending results.

Options for different blade types (e.g., paddle blades, ribbon blades, spiral blades) to cater to specific blending requirements.

Adjustable blending speed and intensity settings to achieve desired texture and homogeneity.

Ø Construction:

Robust and durable construction using high-quality materials to withstand heavy-duty usage.

Stainless steel or food-grade materials for parts that come into contact with ingredients to ensure product safety and hygiene.

Sturdy base and frame to minimize vibrations and enhance stability during operation.

Ø Control Panel:

User-friendly interface with intuitive controls for easy operation.

Digital display for monitoring blending parameters, such as time, speed, and temperature (if applicable).

Programmable settings to store and recall specific blending profiles for consistent results.

Ø Safety Features:

Overload protection to prevent motor burnout and equipment damage.

Emergency stop button for immediate cessation of blending operations.

Safety interlocks and guards to ensure operator protection during operation.

Ø Cleaning and Maintenance:

Easy-to-clean design with smooth surfaces and quick disassembly features for efficient cleaning.

Removable components (e.g., blades, container) for thorough maintenance and sanitation.

Regular maintenance recommendations provided in the user manual for optimal performance and longevity.

Ø Applications:

Versatile applications in industries such as food and beverage, pharmaceuticals, chemicals, cosmetics, and more.

Suitable for blending dry powders, granules, liquids, pastes, and other ingredients.

Please note that the specifications provided are general and can be customized based on specific customer requirements.

Homogenizer

A homogenizer is a device in which dispersion of liquids is achieved by forcing the mixture through a small orifice under very high pressures. A homogenizer is a process or stage which produces a mixture of two or more liquids.

Dispersers

Description:

Introducing our Disperser Agitator—a high-performance solution designed to facilitate efficient dispersion and dissolution of materials in various industries. With its powerful motor, specially designed mixing mechanism, and versatile features, our Disperser Agitator delivers exceptional performance and ensures optimal results.

Download BrochurePowerful Dispersion Capability:

The Disperser Agitator is equipped with a high-speed disperser blade that generates intense shear forces, enabling rapid material breakup and particle size reduction. It ensures efficient dispersion and dissolution of materials, resulting in uniform mixing and enhanced product quality.

Versatile Design:

Our Disperser Agitator is available in different capacities, accommodating a wide range of batch sizes and production requirements. It offers flexibility in dispersion intensity and allows for customization of blade height or immersion depth to achieve precise dispersion control.

Robust Construction:

Built to withstand demanding operating conditions, our Disperser Agitator features a sturdy construction using corrosion-resistant materials such as stainless steel or coated alloys. This ensures durability, longevity, and consistent performance even in harsh environments.

Adjustable Parameters:

The Disperser Agitator provides variable speed control, allowing you to adjust the rotational speed and dispersion intensity according to your specific needs. This flexibility enables fine-tuning of the dispersion process for optimal results.

Easy Installation and Operation:

Our Disperser Agitator offers easy and secure mounting options on tanks, vessels, or mixing containers. The user-friendly control panel facilitates convenient operation, providing intuitive controls for starting, stopping, and adjusting the agitator's speed.

Safety Features:

Safety is a top priority, and our Disperser Agitator incorporates safety interlocks and guards to ensure operator protection during installation, maintenance, and operation. An emergency stop button is provided for immediate shutdown in critical situations.

Wide Industry Applications:

The Disperser Agitator finds applications in various industries, including chemical processing, paint and coatings, pharmaceuticals, food and beverage, and more. Its versatility makes it suitable for dispersing and dissolving powders, pigments, resins, additives, and other materials in liquid or solvent.

Experience the exceptional dispersion capabilities of our Disperser Agitator to enhance your production processes and achieve superior results. With its powerful performance, versatile design, and user-friendly operation, our Disperser Agitator is the ideal solution for your dispersion needs. Contact us today to learn more about how our Disperser Agitator can optimize your manufacturing operations.

Keywords:

disperser agitator, dispersion, dissolution, powerful dispersion capability, versatile design, robust construction, adjustable parameters, easy installation, user-friendly operation, safety features, wide industry applications, chemical processing, paint and coatings, pharmaceuticals, food and beverage, material dispersion, product quality, manufacturing operations.

· · Specifications

Ø

Dispersing Capacity:

Designed to efficiently disperse and dissolve materials in liquid or solvent.

Available in various capacities to suit different batch sizes and production requirements.

Ø Motor Power:

Powerful motor for effective dispersion and creation of high shear forces.

Motor power options may vary (e.g., 2 HP, 5 HP, 10 HP, etc.) based on the specific agitator model and desired dispersion intensity.

Ø Mixing Mechanism:

High-speed disperser blade or impeller specifically designed for rapid material breakup and particle size reduction.

Blade configurations optimized for achieving efficient dispersion and homogenization of the material.

Ø Construction:

Sturdy construction using durable and corrosion-resistant materials (e.g., stainless steel, coated alloys) to withstand demanding operating conditions.

Robust design to withstand the forces generated during high-speed dispersion.

Ø Adjustable Parameters:

Variable speed control to adjust the agitator's rotational speed and dispersion intensity.

Options for adjustable blade height or immersion depth to control the level of shear forces applied to the material.

Ø Mounting and Installation:

Easy and secure mounting on tanks, vessels, or mixing containers.

Various mounting options available, such as flange mounting or clamp mounting, to accommodate different equipment configurations.

Ø Control Panel:

User-friendly control panel for convenient operation and adjustment of mixing parameters.

Intuitive controls for starting, stopping, and adjusting the agitator's speed or other relevant functions.

Ø Safety Features:

Safety interlocks and guards to prevent accidents and ensure operator safety during installation, maintenance, and operation.

Emergency stop button for immediate shutdown in case of emergencies or unforeseen situations.

Ø Maintenance:

Easy-to-access design for routine maintenance and cleaning.

Regular maintenance recommendations provided in the user manual for optimal performance and longevity.

Ø Applications:

Suitable for a wide range of industries, including chemical processing, paint and coatings, pharmaceuticals, food and beverage, and more.

Ideal for dispersing and dissolving materials such as powders, pigments, resins, additives, and other substances into liquid or solvent.

Please note that the specifications provided are general and can be customized based on specific customer requirements and the intended application.IBC Agitator

Description:

Introducing our IBC Agitator—a state-of-the-art solution designed to enhance the mixing and blending processes in Intermediate Bulk Containers (IBCs). Our IBC Agitator is equipped with cutting-edge features and optimized for efficient operation, delivering superior performance in a wide range of industries.

Download BrochurePowerful Mixing Capability:

The IBC Agitator utilizes a robust motor and specially designed impellers to ensure thorough and efficient mixing of liquids, suspensions, and powders within IBCs. It provides excellent agitation, allowing for consistent blending and uniform distribution of substances.

Versatile Design:

Our IBC Agitator is designed to accommodate various container sizes and shapes, ensuring compatibility with different types of IBCs. It can be easily adjusted and configured to meet specific mixing requirements, providing versatility and adaptability to your processes.

Easy Installation and Operation:

The IBC Agitator features a user-friendly design that simplifies both installation and operation. It can be quickly and securely mounted onto IBCs, and its intuitive controls enable hassle-free adjustment of mixing parameters, ensuring smooth and efficient operation.

Durable and Reliable:

Built with durability in mind, our IBC Agitator is constructed using high-quality materials that withstand rigorous industrial environments. It is resistant to corrosion, abrasion, and chemical damage, ensuring long-lasting performance and minimal maintenance requirements.

Energy-Efficient Performance:

The IBC Agitator is engineered to optimize energy consumption without compromising performance. Its efficient motor and advanced control systems minimize power usage, resulting in cost savings and environmental sustainability.

Safety Features:

Safety is paramount in industrial operations. Our IBC Agitator incorporates safety features such as overload protection and emergency stop functions, ensuring operator protection and preventing equipment damage.

Wide Industry Applications:

The IBC Agitator is suitable for various industries, including chemical manufacturing, food and beverage production, pharmaceuticals, and more. Its versatility makes it an indispensable tool for processes requiring efficient mixing and blending within IBCs.

Experience the power and efficiency of our IBC Agitator to streamline your mixing processes, enhance product quality, and improve overall productivity. With its powerful performance, easy operation, and durability, our IBC Agitator is the ideal solution for your mixing needs. Contact us today to learn more about how our IBC Agitator can optimize your industrial operations.

Keywords:

IBC agitator, mixing, blending, efficient operation, versatile design, easy installation, durable, reliable, energy-efficient, safety features, wide industry applications, industrial mixing, IBC container, industrial blending, product quality, productivity.

· Specifications:

Pr product Specifications: IBC Agitator

Ø Compatibility:

Designed to fit Intermediate Bulk Containers (IBCs) of various sizes and configurations.

Compatibility with standard IBC dimensions (e.g., 275 gallons, 330 gallons) as well as custom IBCs.

Ø Motor Power:

Powerful motor for efficient agitation and mixing performance.

Motor power options may vary (e.g., 0.5 HP, 1 HP, 2 HP, etc.) based on the specific agitator model.

Ø Mixing Mechanism:

Specially designed impellers or blades for effective mixing and blending of liquids, suspensions, and powders within IBCs.

Various impeller configurations available (e.g., axial flow, radial flow, hydrofoil) depending on the desired mixing requirements.

Ø Mounting and Installation:

Easy and secure mounting onto the IBC, ensuring stability during operation.

Quick and straightforward installation process with minimal downtime.

Ø Adjustable Parameters:

Variable speed control to adjust the agitator's rotational speed based on the blending requirements.

Optional features for adjusting mixing intensity, such as pitch angle or blade clearance, to achieve desired results.

Ø Construction:

Robust construction using durable materials (e.g., stainless steel, corrosion-resistant alloys) to withstand demanding industrial environments.

Suitable materials for contact with different types of liquids or chemicals to ensure compatibility and product integrity.

Ø Control Panel:

User-friendly control panel for easy operation and monitoring of mixing parameters.

Intuitive controls for adjusting speed, starting and stopping the agitator, and other relevant functions.

Ø Safety Features:

Overload protection mechanism to prevent motor damage in case of excessive loads.

Emergency stop button for immediate cessation of agitator operation.

Safety interlocks or guards to ensure operator safety during installation, maintenance, and operation.

Ø Maintenance:

Easy-to-clean design with accessible components for routine maintenance and cleaning.

Regular maintenance recommendations provided in the user manual for optimal performance and longevity.

Ø Applications:

Suitable for a wide range of industries, including chemical manufacturing, food and beverage, pharmaceuticals, and more.

Ideal for blending, mixing, or suspending ingredients, chemicals, or formulations within IBCs.

Please note that the specifications provided are general and can be customized based on specific customer requirements and the intended application.